Equipment & Capabilities

Skyline is a family-owned molding company dedicated to delivering quality parts on time. Our facility has eight machines, ranging from 90 to 500 tons, allowing us to mold various parts in small and large quantities. Our in-house tooling department ensures molds are well-maintained, and we can make engineering changes quickly.

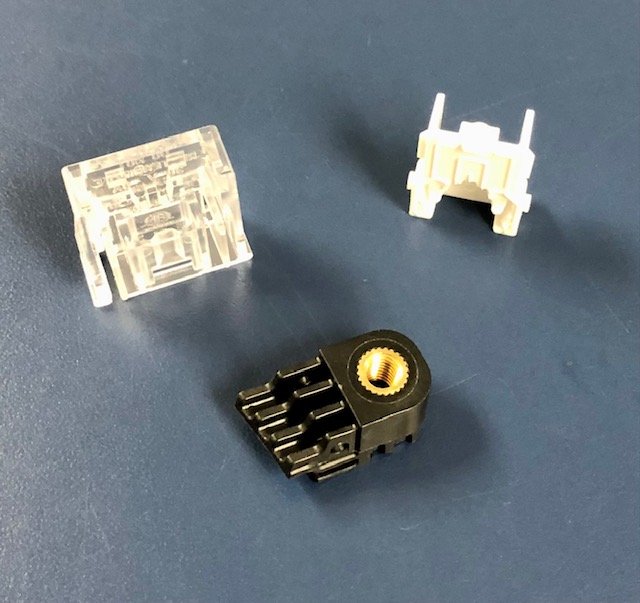

2K Injection Molding

Capabilities

-

Injection Molding

Overmolding

2K Molding

Insert Molding

PPAP

Automation

Part Decoration

Ultrasonic Welding

Wide Range of Plastic Materials

Prototyping & Testing

-

Mold Manufacturing

Engineering Changes

Repair Work

Preventative Maintenance

Mold Design

3D Printing

Moldflow

Gauges & Fixtures

End of Arm Tools for Automation

MUD Frame & Inserts Tooling

-

ENGEL VICTORY 2K 500 Ton

ROBOSHOT 138 ton

ROBOSHOT 198 ton

ROBOSHOT 198 ton

ROBOSHOT 240 ton

ROBOSHOT 330 ton

MILACRON MTS 90 ton

MILACRON MTS 140 ton

All presses have 3 or 5 axis robots for part removal & conveyors for streamline automation.

Beside the press dryers

Central Chiller System

All presses newer than 2014 and energy efficient

5 All Electric Machines

3 Servo Hydraulic Machines

2K Molding capability with rotating platen - Engel 2K 500 Ton

Parts Gallery

Facilities

Our facilities are climate-controlled and energy efficient. Our box truck is available for local deliveries.